Mechanical watches have been admired for centuries, known for their craftsmanship, precision, and the artistry involved in their construction. But how exactly do these timepieces work without relying on batteries or modern electronics? In this post, we’ll break down the inner workings of a mechanical watch, explaining each component and its role in keeping time.

Whether you’re a watch enthusiast or simply curious about the mechanics behind these timeless pieces, this guide will help you understand the magic inside every mechanical watch.

What is a Mechanical Watch?

A mechanical watch is a timepiece powered entirely by mechanical components rather than electricity or refined quartz technology. Unlike quartz watches, which use a battery, mechanical watches rely on a mainspring and a series of gears, wheels, and springs to keep accurate time. These watches are known for their longevity, craftsmanship, and the fine detail that goes into their assembly.

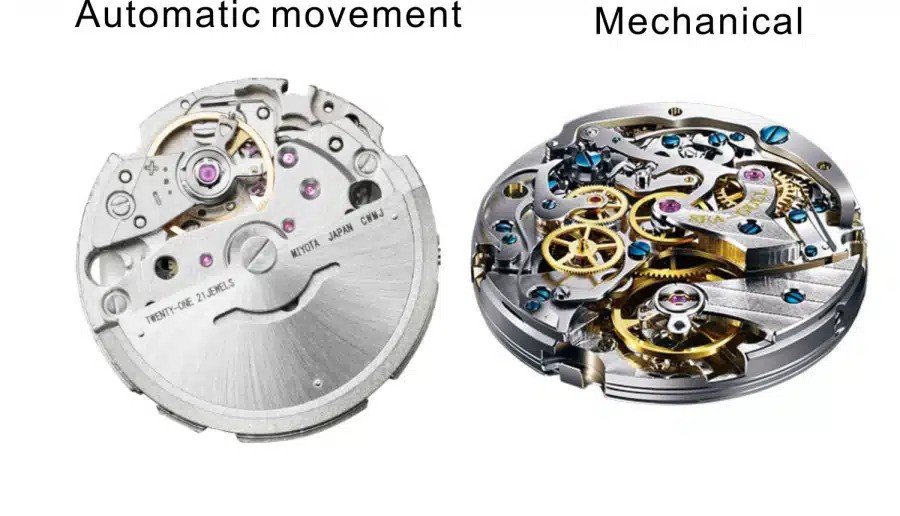

There are two types of mechanical watches:

- Manual Mechanical Watch: Requires regular winding by hand.

- Automatic (Self-Winding) Watch: Uses the motion of the wearer’s wrist to wind itself.

The Key Components of a Mechanical Watch

- Mainspring: The mainspring is the power source of the watch. It is a coiled spring that stores energy when wound. Whether wound manually or by wrist movement, the energy stored in the mainspring is gradually released to power the watch.

- Gear Train: The gear train is responsible for transferring the energy from the mainspring to the escapement. This set of gears reduces the speed of the mainspring’s unwinding, making sure the energy is distributed at the right intervals.

- Escape Wheel: This is the heart of the watch’s accuracy. The escapement controls the release of energy from the mainspring in evenly timed intervals. It ensures that the gears move precisely, allowing the watch to measure time accurately.

- Balance Wheel: The balance wheel works with the escapement to regulate the energy release. It swings back and forth in a consistent rhythm, acting like a pendulum. This oscillation is what allows the watch to “tick” at regular intervals, usually several times per second.

- Dial Train and Hands: The dial train connects the gear train to the hands of the watch, converting the energy into the movement of the hour, minute, and second hands. This final step allows the mechanical process to be translated into the time displayed on the watch face.

How Energy Moves Through a Mechanical Watch?

The process begins with the mainspring being wound, storing energy. As the mainspring unwinds, this energy is transmitted through the gear train. The gear train reduces the speed at which the energy is transferred, ensuring that it is released at a controlled pace.

Next, the escapement regulates this release of energy, allowing the balance wheel to oscillate at a steady rate. The balance wheel and escapement work together to control the timing of each “tick” of the watch. This controlled movement is then passed through the dial train, which moves the hands of the watch to display the time.

The Role of Manual Winding vs. Automatic Winding

A manual mechanical watch needs to be wound by hand using the crown (the small knob on the side of the watch). This process tightens the mainspring, storing the energy that will be released over time. Depending on the watch, it may need to be wound every 24 to 48 hours.

Automatic (or self-winding) mechanical watches, on the other hand, wind themselves using the natural movement of the wearer’s wrist. Inside the watch is a rotor, a weighted component that spins with wrist movement, winding the mainspring automatically. This makes automatic watches more convenient, as they don’t require daily winding if worn regularly.

Why Choose a Mechanical Watch?

Mechanical watches are often seen as symbols of craftsmanship and tradition. Here are some reasons why people choose mechanical watches over quartz models:

- Craftsmanship: Each mechanical watch is a marvel of engineering, made up of hundreds of tiny parts working in harmony.

- Longevity: Mechanical watches, with proper care and maintenance, can last generations. Some are even passed down as heirlooms.

- Aesthetics: The smooth, sweeping motion of the second hand in a mechanical watch is often preferred over the “ticking” movement of quartz watches.

- Artistry: Many mechanical watches feature transparent casebacks, allowing you to see the intricate movement of the gears, escapement, and balance wheel.

The Importance of Maintenance

Owning a mechanical watch requires a certain level of care. Regular servicing is essential to keep it running smoothly. This typically involves cleaning, oiling, and adjusting the internal components. Most manufacturers recommend servicing a mechanical watch every 3 to 5 years.

Without proper maintenance, the lubricants inside the watch can dry up, causing friction and wear on the delicate gears and springs.

Conclusion

Mechanical watches are a blend of art, science, and history. Their ability to keep time through an intricate system of gears and springs, without the need for modern technology, makes them highly valued by collectors and enthusiasts alike. Whether you choose a manual or automatic mechanical watch, you’re not just wearing a timepiece—you’re wearing a piece of engineering history.

Investing in a mechanical watch is a statement of appreciation for craftsmanship and tradition. And now that you know how they work, you can truly appreciate the intricate beauty of these timeless creations.

Without proper maintenance, the lubricants inside the watch can dry up, causing friction and wear on the delicate gears and springs.